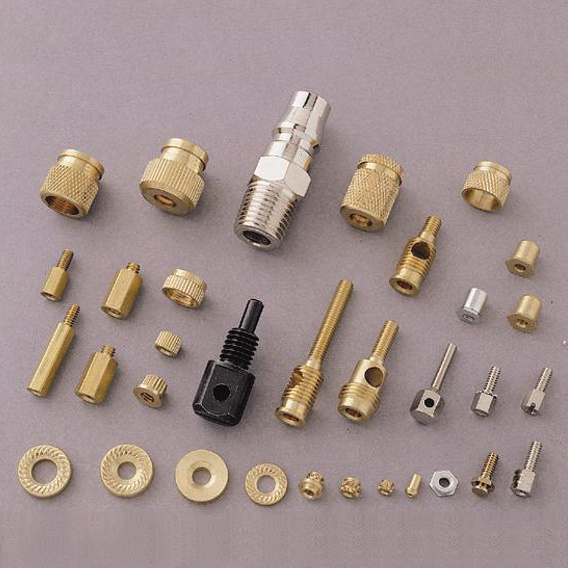

Turning parts

Our company is a professional manufacturing factory of precision hardware, producing all kinds of standard fasteners, stamping parts and all kinds of non-standard products, with the technical ability to develop new products. The introduction of a full set of advanced equipment and molds, digestion and absorption of domestic technology, since its establishment more than ten years of continuous innovation, to provide customers with various series of high quality fasteners and stamping products.

Key words:

Fasteners | non-standard parts | stamping parts

Classification:

Product Description

Turned parts are a kind of parts that are processed on a lathe by a lathe, and the shape and size of the blank are changed by the rotary motion of the workpiece and the linear or curved motion of the tool, and processed to meet the requirements of the drawing. Turning is a method of cutting the workpiece on the lathe by rotating the workpiece relative to the tool. The cutting energy of turning is mainly provided by the workpiece rather than the tool. Turning is the most basic and common cutting method, and it occupies a very important position in production. Turning is suitable for machining revolving surfaces. Most workpieces with revolving surfaces can be processed by turning methods, such as inner and outer cylindrical surfaces, inner and outer conical surfaces, end surfaces, grooves, threads and revolving forming surfaces. The tools used are mainly turning tools. The precision of turning processing is generally IT11-IT7, and some can reach IT6, and the surface roughness Ra can reach 12.5-08um. The parts processed by turning are called turning parts. There are many types of turning parts, and it is famous for hard turning to maintain the thermal stability of the parts.

Turned parts processing steps

Before operation

1 Before work, strictly use protective equipment according to the regulations, tie up the cuffs, do not wear scarves or gloves, and female workers should put their defenses in their hats. The operator must stand on the foot pedal.

2 All parts of the bolts, stroke limits, signals, safety protection (safety) devices, mechanical transmission parts, electrical parts, and lubrication points should be strictly inspected, and only after the reliability is confirmed, it can be started.

3 All kinds of machine tool lighting application safety voltage, voltage shall not be greater than 36 volts.

In operation

1 The work, clamp, tool and workpiece must be clamped firmly. All types of machine tools should be idling at a low speed after starting up, and they can be officially operated after everything is normal.

2 Tools and other things are forbidden to be placed on the track surface of the machine tool and on the workbench. It is not allowed to remove iron filings by hand, and special tools should be used to clean it.

3 Before starting the machine tool, observe the surrounding dynamics. After the machine tool is started, stand in a safe position to avoid the moving parts of the machine tool and iron filings.

4 During the operation of various types of machine tools, it is not allowed to adjust the speed change mechanism or stroke, and it is not allowed to touch the transmission part, the workpiece in motion, the cutting tool and other working surfaces in the process, and it is not allowed to measure any size during operation. It is forbidden to drive through the machine tool. Partially pass or take tools and other items.

5 When abnormal noise is found, the machine should be stopped for maintenance immediately, and the machine must not be operated forcibly or with disease, and the machine tool is not allowed to be overloaded.

6 During the processing of each machine part, strictly implement the process discipline, read the drawings clearly, see the control points, roughness of each part and the technical requirements of the relevant parts, and determine the processing procedures of the parts.

7 Stop the machine when adjusting the machine speed, stroke, clamping workpiece and tool, and wiping the machine tool. It is not allowed to leave the work post while the machine is running, and must stop and cut off the power when leaving for some reason.

After operation

1 The raw materials to be processed and processed finished products, semi-finished products and waste materials must be stacked in designated places, and various tools and cutting tools must be kept intact and good.

2 After the operation, you must cut off the power supply, remove the tool, put the handles in the neutral position, and lock the switch box.

3 Clean the equipment sanitary, clean the iron filings, and lubricate the guide rails to prevent rust.

Turning parts processing regulations are one of the process documents that stipulate the machining process and operation methods of parts. It is to write a more reasonable process and operation method in a prescribed form into a process document under specific production conditions. Used to guide production after approval. Turned parts processing procedures generally include the following: the process route of the workpiece processing, the specific content of each process and the equipment and process equipment used, the inspection items and inspection methods of the workpiece, the cutting amount, the time quota, etc.

More products

Welcome your message consultation

If you are interested in our products, please leave your demand, we will contact you as soon as possible, thank you!